- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

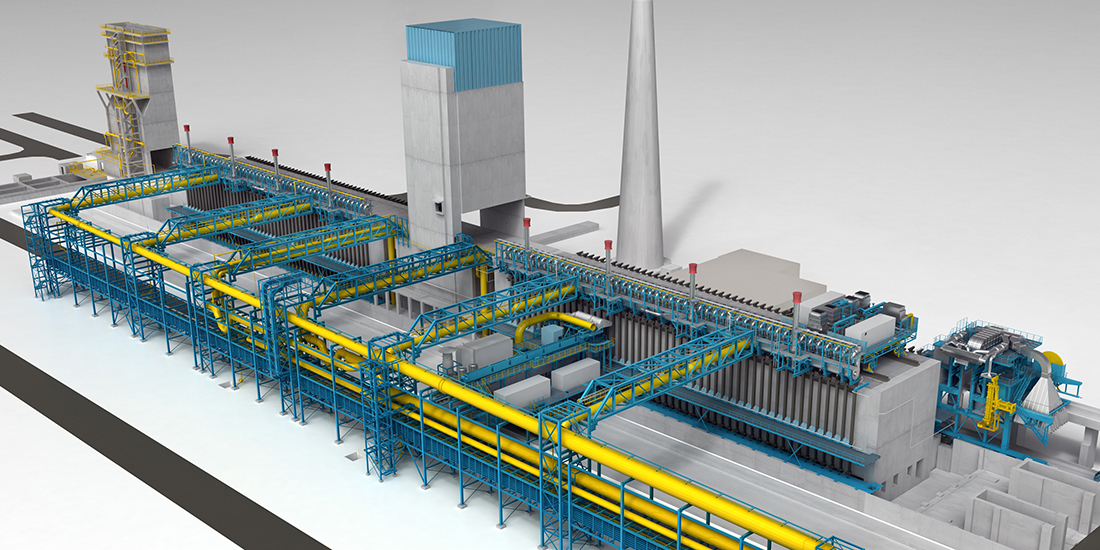

Cokemaking

Features for Environmental Compliance

Proprietary items for

eco-friendly coke productionAs coke plant operators have to comply with ever more challenging regulations in terms of emission control and environmental protection, Paul Wurth pursues a policy of continuous improvement and development of its technological tools and solutions, thus proposing a series of innovative special design features:

- Smokeless charging system for top and stamp charged batteries

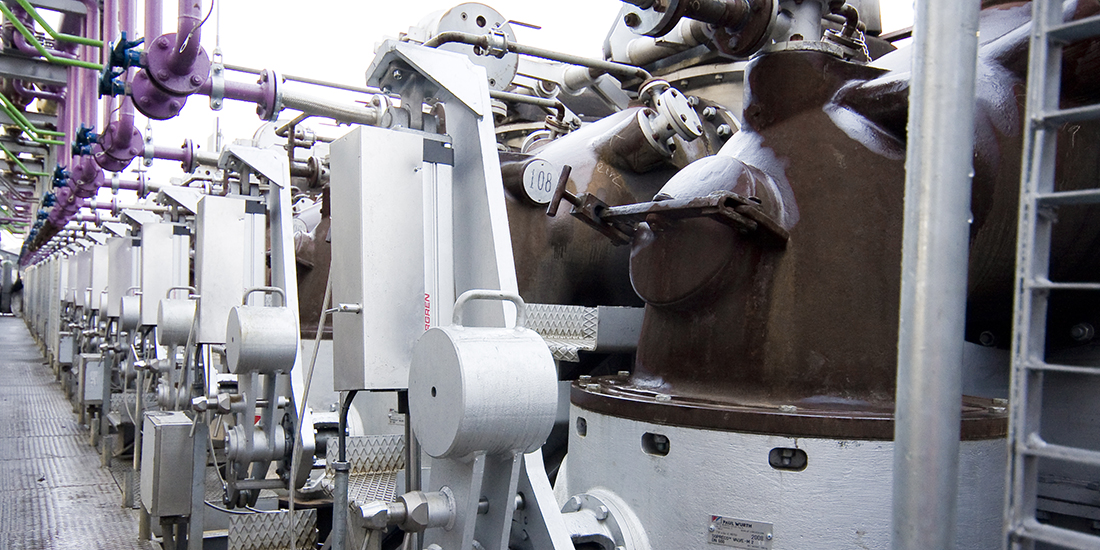

- SOPRECO® system for controlling the pressure for each individual oven in a coke oven battery during the entire coking process and thus reducing fugitive emissions up to 90%

- COKEXpert™ level-2 automation systems for improving the operational and environmental performances

- Specially designed coke oven doors suiting the actual requirements for a low-maintenance and environmentally friendly system

- Heating system for minimal NOx and CO concentrations, uniform temperature distribution and optimised fuel consumption

- Specially designed bracing system for high heating wall stability and gas tightness

- Advanced quenching technologies

- Coal and coke spillage collecting systems

- Pushing emission control system on coke side

- On board or land based dedusting system for pusher machine

Related News

-

Yunnan Coal & Energy relies on Paul Wurth low-emission coke making technology

More information -

+2K SOPRECO valves sold make cokemaking more ecological

More information

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking