- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

Shaping the future

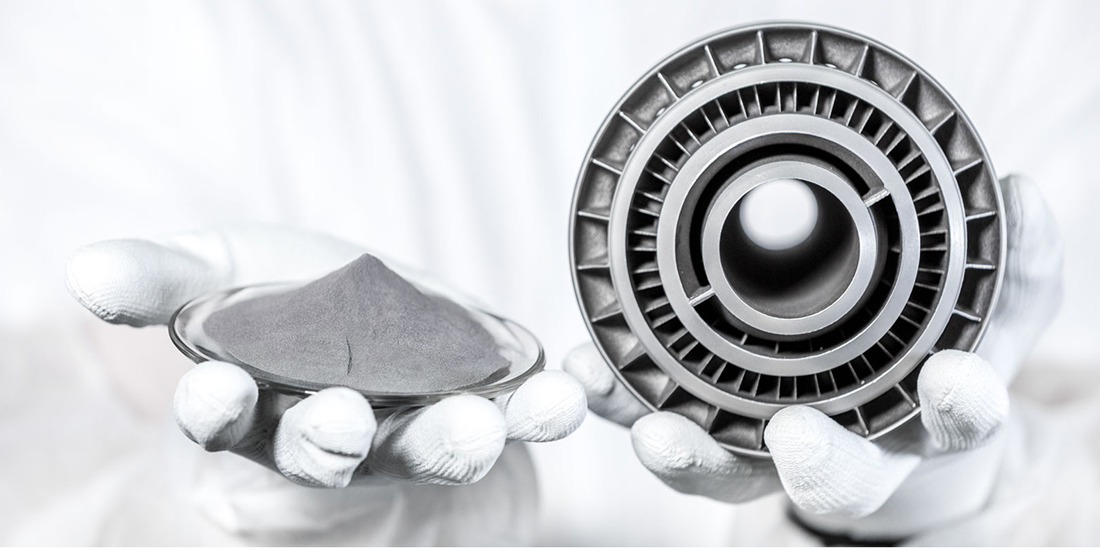

Additive Manufacturing

New horizons for equipment design

Additive manufacturing, also known as 3D printing, is a bottom-up manufacturing process that allows producing components or mechanical systems of complex design. Based on 3D data files, the parts are produced directly in their final geometry by means of layer-by-layer addition of material, compared to e.g. machining which is a subtractive process.

The technology has evolved from prototyping applications to a reliable manufacturing process on industrial scale. It is suitable to produce complex parts in many different materials, including a wide range of polymers, metals or even ceramics.

With additive manufacturing, equipment can be (re-)designed to its functions, with various advantages such as a reduced number of parts, significant weight saving combined with high mechanical strength and smart integration of increased functionalities.

In cooperation with the SMS group, Paul Wurth is also building up know-how in designing and optimising selected parts for additive manufacturing, with first equipment already in operation.

First 3D-printed component installed in a blast furnace

Paul Wurth engineers are proud to have designed the very first 3D-printed titanium component ever installed in a blast furnace. The piece is part of a monitoring device developed and supplied by TMT Tapping Measuring Technology, allowing real-time visual monitoring of the blast furnace top cone area. Thanks to additive manufacturing techniques, the design of the component could be optimised so as to increase its lifetime significantly. Moreover, 3D-printing is reducing the production and delivery time as well as the cost of these spare parts.

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking