- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

Shaping the future

Stepwise CO2 Reduction

Towards the CO2-friendly blast furnace

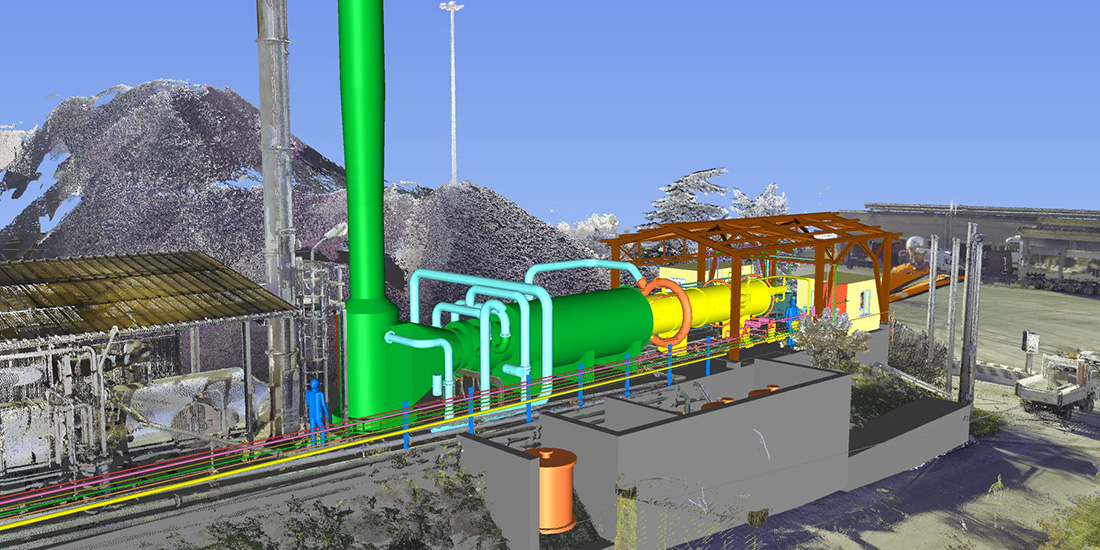

Before steelmaking customers decide to opt for a complete changeover in technology, stepwise but substantial reduction of the CO2 footprint can be reached in the short and mid-term by deploying innovative, resource-saving solutions to the existing installed equipment.

Currently, Paul Wurth is extending its offering of technologies designed to gradually reduce CO2 emissions in the classic blast furnace process, thereby creating a sensible balance between ambitious environmental targets and economic constraints. Our “Enhanced Blast Furnace” is capable of substantially reducing the carbon footprint of this established and proven technology!

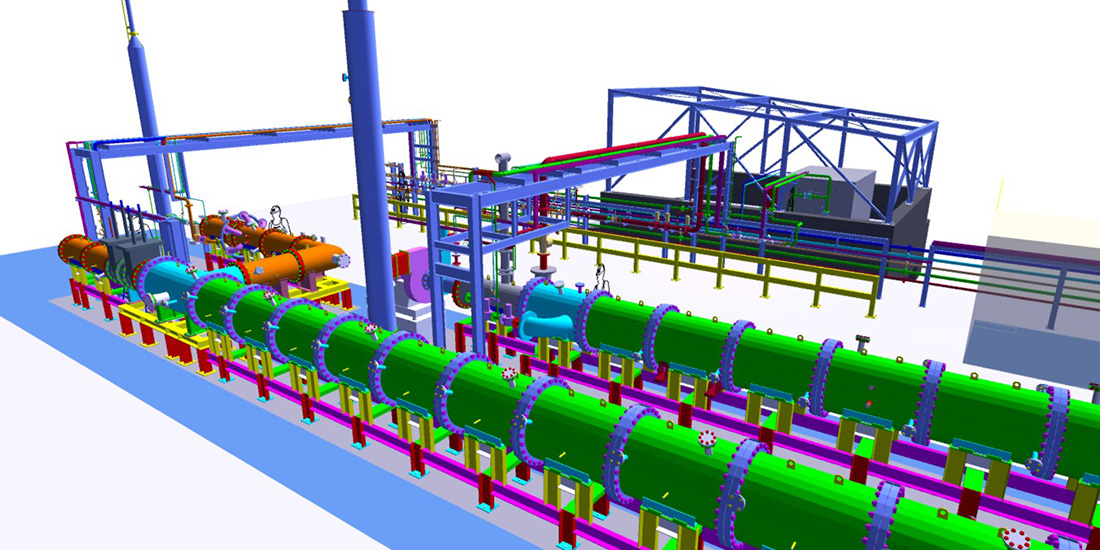

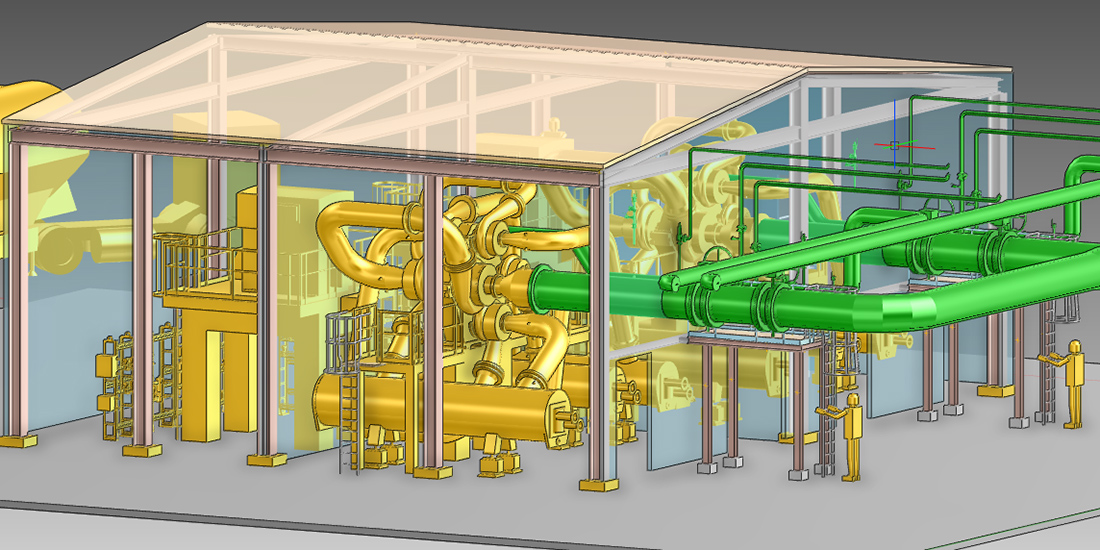

The primary aim is to achieve the efficient metallurgical use of off-gases – particularly coke oven gas, blast furnace gas and converter gas – from the steel production process. Because of its high calorific value, coke oven gas is a source of energy that has the potential to replace some of the coke used in the blast furnace and thereby save CO2. One possibility is to inject coke oven gas into the blast furnace via the hot blast tuyeres. Another possibility is to inject the coke oven gas into the lower shaft of the blast furnace. As part of this technology, Paul Wurth is working on developing a coke oven gas reforming technology based on reforming and/or partially oxidising the coke oven gas. Paul Wurth is also laboratory testing the transformation of both blast furnace and coke oven gas into a hot synthetic gas by means of a modified hot blast stove based on dry reforming.

In all, Paul Wurth’s strategy is based on the utilisation of syngas, a mixture of carbon monoxide and hydrogen, in the blast furnace, but also on the addition of biomass in replacement of fossil fuels, which allows to integrate in an efficient way more and more hydrogen into the blast furnace / basic oxygen furnace process.

Related News

-

Pilot dry reforming plant commissioned in Dillingen in success for Paul Wurth

More information -

Paul Wurth to further boost efficiency of new MMK blast furnace

More information -

NextChem and Paul Wurth join forces to develop innovative low-carbon solutions for the steel industry

More information -

HKM relies on Paul Wurth engineering for feasibility study on Ecoloop Syngas plant

More information -

CAP and Paul Wurth join forces to decarbonise iron ore mining and steelmaking operations in Chile

More information -

Italiana Coke and Paul Wurth to test new CO2 reducing technology

More information -

Paul Wurth and the steel partners Dillinger and Saarstahl join forces on development of dry reforming technology

More information -

Paul Wurth books new order for Coke Oven Gas Compression and Injection Technology at HKM

More information -

Rio Tinto teams up with Paul Wurth and SHS-Stahl-Holding-Saar on low-carbon iron in Canada

More information

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking