- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

News

29th April 2021

Paul Wurth and the steel partners Dillinger and Saarstahl join forces on development of dry reforming technology

Dilllingen/Völklingen/Luxembourg, 29 April 2021. Saarstahl and Dillinger cooperate with Paul Wurth, a company of SMS group, to further develop the technology of dry reforming of coke oven gas with blast furnace gas developed by Paul Wurth. A cooperation agreement to this effect was signed in 2020. The pilot plant is to be taken into operation in the summer at the site of the joint subsidiary of Dillinger and Saarstahl, ROGESA Roheisengesellschaft Saar mbH, in Dillingen.

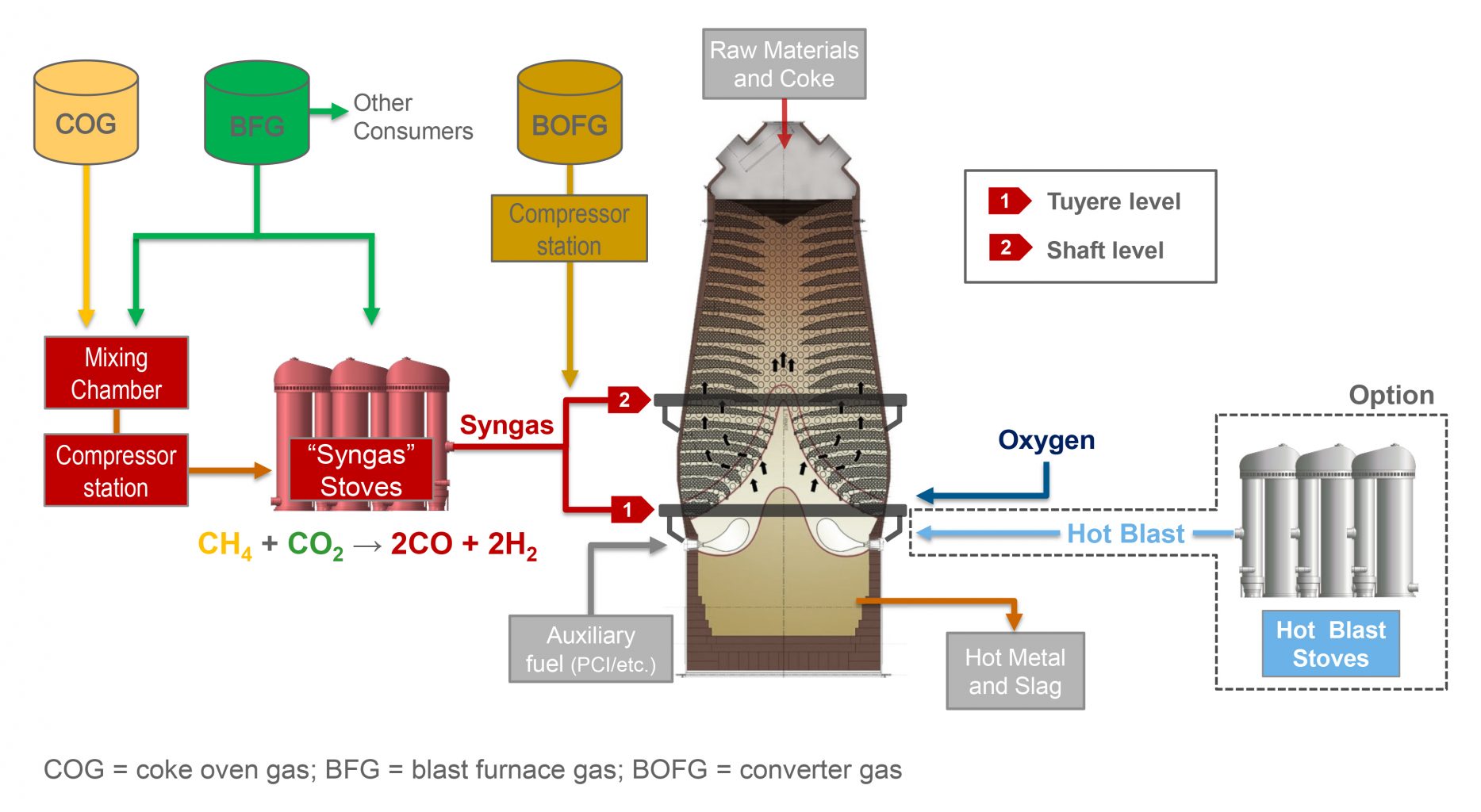

General principle of Paul Wurth’s dry reforming process The dry reforming process allows the conversion of coke oven gas into a hot reducing gas or syngas that is injected in the blast furnace at tuyere or shaft level. The mixture of coke oven gas and blast furnace gas is compressed and heated-up in a regenerative heat exchanger of similar design than a traditional hot stove. At high temperature, the methane contained in the coke oven gas will react with the CO2 contained in the blast furnace gas to produce hydrogen and carbon monoxide.

The injection of this hot reducing gas into the blast furnace entails a significant reduction in coke consumption. Such use of steelmaking gases for metallurgical purposes rather than for thermal purposes, translates into a significant reduction in CO2 emissions of up to 12%. The use of hydrogen can further improve and almost double the CO2 saving potential.

The first step in the development of the dry reforming technology is the construction of a pilot plant, which allows testing the dry reforming process at small scale with industrial gases. A further objective of the pilot plant is to test materials and components in regards to their suitability for the construction of an industrial scale plant. This is particularly important for the selection of refractory materials used in the regenerative heat exchanger. The start-up of the pilot plant is scheduled for summer 2021.

In the subsequent phases of the cooperation, it is planned to scaled-up the process to semi-industrial and later industrial scale with the support of public funding, by producing larger amounts of hot syngas and inject them at shaft level in one of the two blast furnaces in Dillingen. Elaboration of a blast furnace shaft injection technology is thus part of the dry reforming development.

The cooperation agreement provides Paul Wurth the opportunity to test the dry reforming process under industrial-like conditions, which will boost the development of the new technology. For Dillinger and Saarstahl, the future full-scale implementation of this technology will considerably decrease the carbon footprint and allow taking a next step forward towards green steel production.

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking