- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

Blast Furnace Ironmaking

Modern Blast Furnace Design

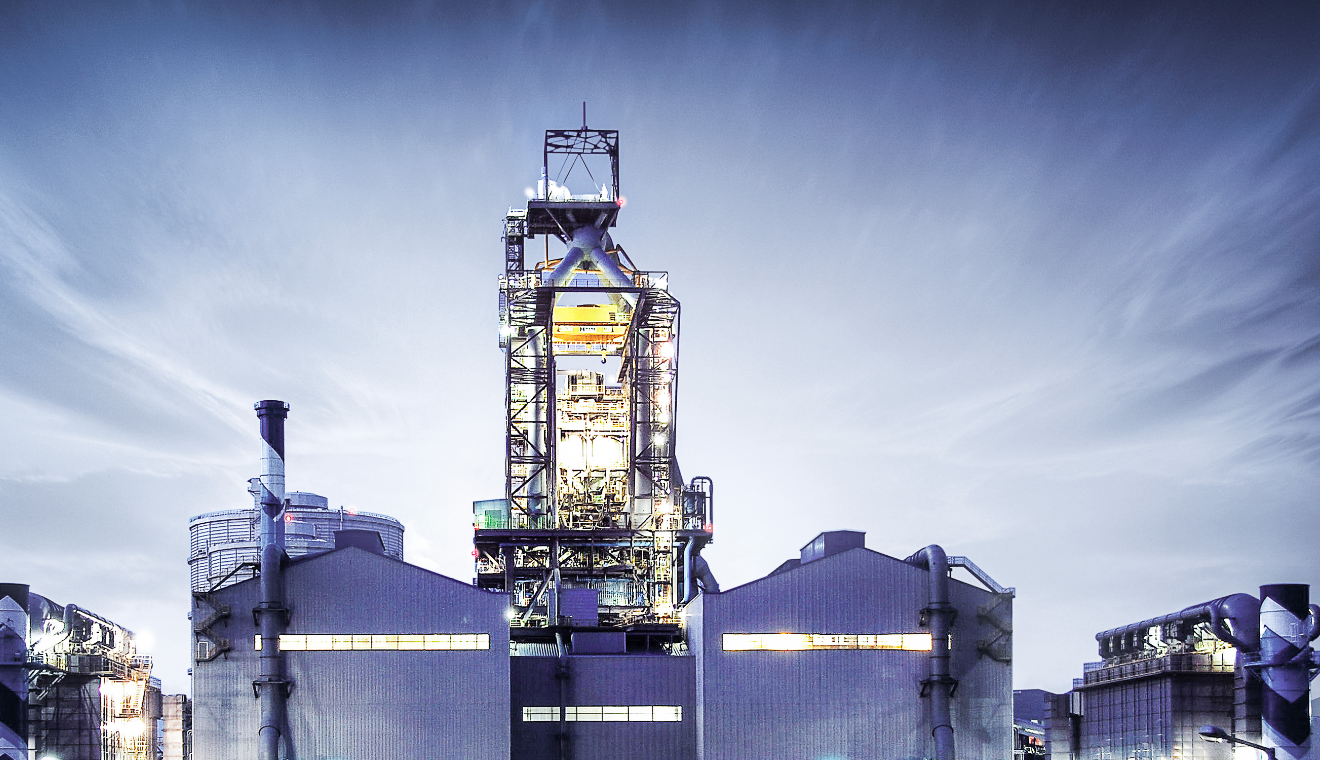

With regard to the available raw materials base, the design of the furnace proper is fundamental to reliable operation, metallurgical performance, sustained high productivity and long campaign life. For both new installations and reactor rebuilds, Paul Wurth’s modern blast furnace designs are based on the concept of a free-standing, self-supporting vessel with high-quality refractories and a cooling concept which allows a thin-wall construction over the entire height of the furnace. A surrounding square tower supports the top structure and provides access to the furnace shell and attached equipment.

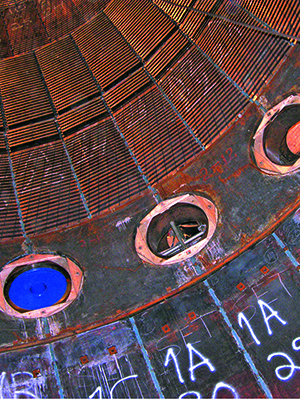

Efficient cooling is required to balance the thermal load and associated wear of the inner lining of the furnace, and to protect the shell and the wall cooling elements. Paul Wurth acquired a unique know-how in blast furnace cooling. Our system operates on more than 90 blast furnace installations worldwide. Incorporating our copper and cast iron staves, we offer state-of-the-art cooling solutions for your optimum blast furnace campaign. Paul Wurth strives to optimise the cooling systems in order to reduce investment and running costs, while ensuring the necessary cooling efficiency and availability of the cooling elements and circuits.

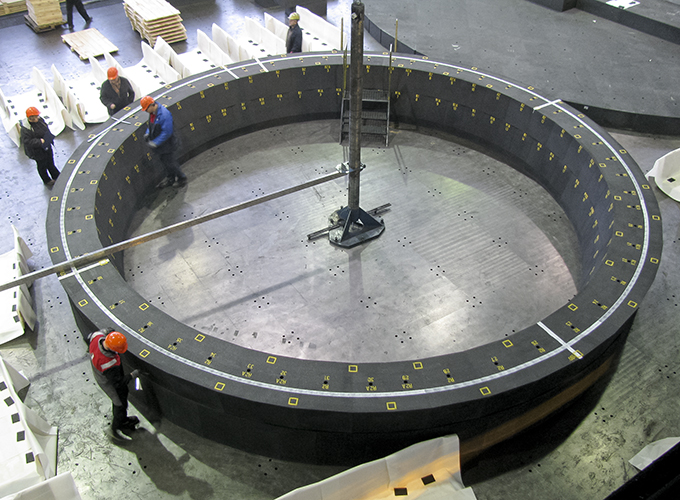

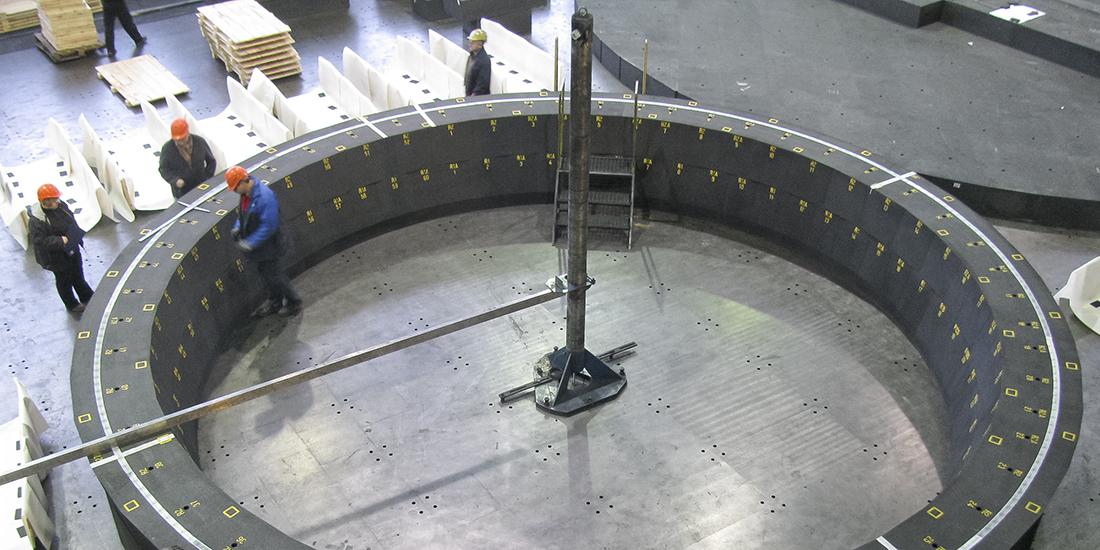

With more than 300 blast furnace linings since 1970 – either new installations or partial relines –, Paul Wurth is one of the most experienced companies in the field of refractory design and application, material supply and installation supervision. Our extensive expertise consists of the know-how gained during numerous projects and on a long-term, close cooperation with dedicated refractory workshops. On a continuous basis, we pursue our own R&D activities and cooperate with plant operators and customers in finding the optimum blast furnace linings and installation techniques. Paul Wurth offers state-of-the-art engineering and on-site services, design calculations, and supply of the complete range of blast furnace refractories.

Related News

-

MMK selects Paul Wurth for construction of new blast furnace

More information -

MMK selects Paul Wurth for modernisation of Blast Furnace cooling system

More information -

Třinecké Železárny awards blast furnace hearth reline to Paul Wurth

More information

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking