- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

Shaping the future

Green Steel

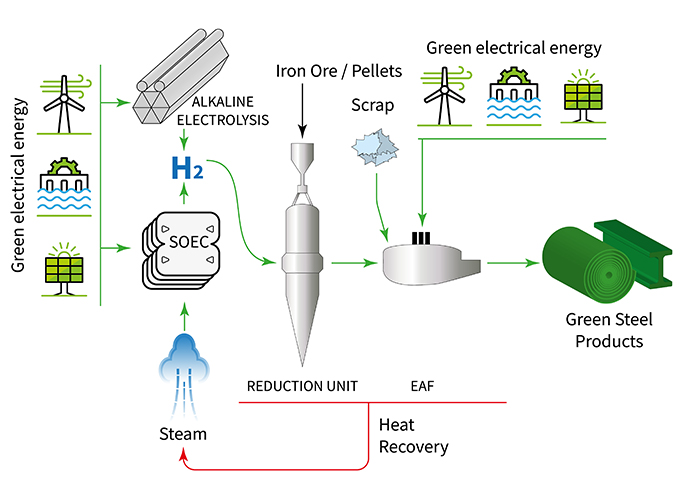

Our core market, the steel sector, is currently facing major policy challenges, particularly in terms of energy and climate. The iron and steel industry is among the biggest industrial emitters of greenhouse gases, accounting for up to 7% of global CO2 emissions. Under the Paris Climate Agreement to combat global warming, steelworks owners and operators must take drastic measures to meet the targets for the future reduction of CO2 emissions. One such scenario is hydrogen-based iron ore reduction, which replaces the fossil carbon with green hydrogen in the reduction process. The challenge here, however, is to produce renewable hydrogen economically on an industrial scale. Many countries all over the world roll out their national energy strategies with action plans for energy transition and a hydrogen based economy.

Many leading steelmakers have already integrated carbon-neutral steelmaking into their vision and the race to the first industrially produced green steel products is gaining momentum. This global drive towards decarbonisation of the industry illustrates that Paul Wurth’s strategy to develop CO2 reducing, innovative green technologies is on the right track. Relying on our long-standing process know-how and the co-operation with partners, the Group investigates in detail the feasibility of a H2-based Direct Reduction (DR) plant. Besides the technical integration of H2 generation with huge production capacity and the adaptation of the classical natural gas based DR technology to a H2-based solution, significant efforts are dedicated to assess and optimise the business case of the industrial configuration.

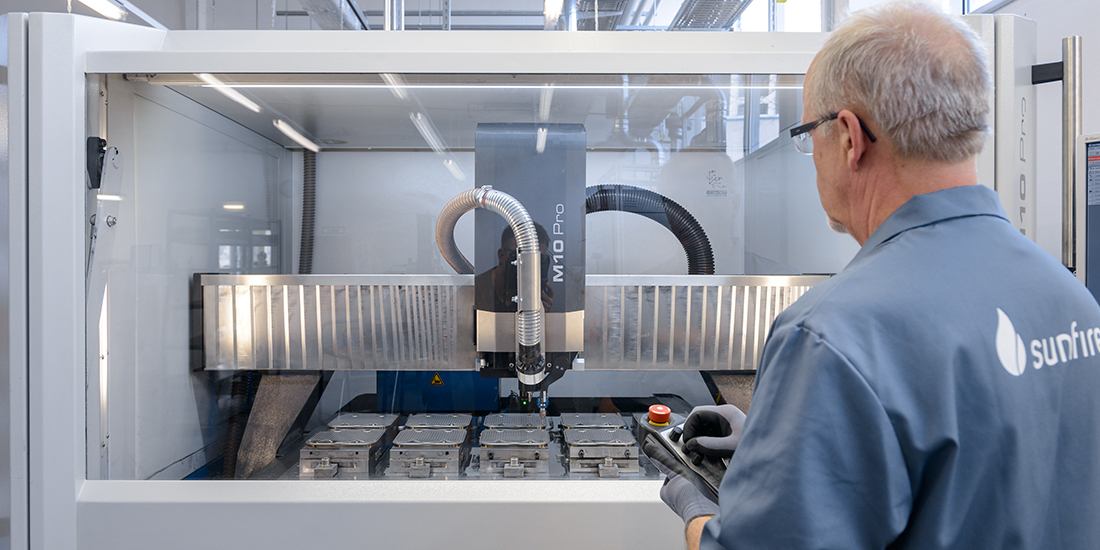

In 2019, Paul Wurth took a decisive step with a 20% participation in the German cleantech company Sunfire GmbH. Sunfire develops and produces high-temperature electrolysers (SOEC) and high-temperature fuel cells (SOFC). Green hydrogen is produced using green electricity in an efficient high-temperature electrolyser, using waste heat generated, for example, by industrial processes.

With the decarbonisation of the industry and the technological transformation affecting integrated steelmaking, new opportunities are arising. By bundling the competences and strengths of both Paul Wurth, focussed on the primary phase of steelmaking, and SMS group, specialised in the down-stream part of the steelmaking process, we are today a credible partner when it comes to discuss hydrogen based technologies with our customers and to lead the transition towards carbon-free steel production.

Related News

-

“Green steel” initiative: cutting carbon with H2Syngas

More information -

GrInHy2.0: Sunfire delivers the world’s largest High-Temperature Electrolyzer to Salzgitter Flachstahl

More information -

Paul Wurth becomes new Lead Investor and Technology Partner of Sunfire

More information -

University of Luxembourg and Paul Wurth create Chair in Energy Process Engineering

More information

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking