- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

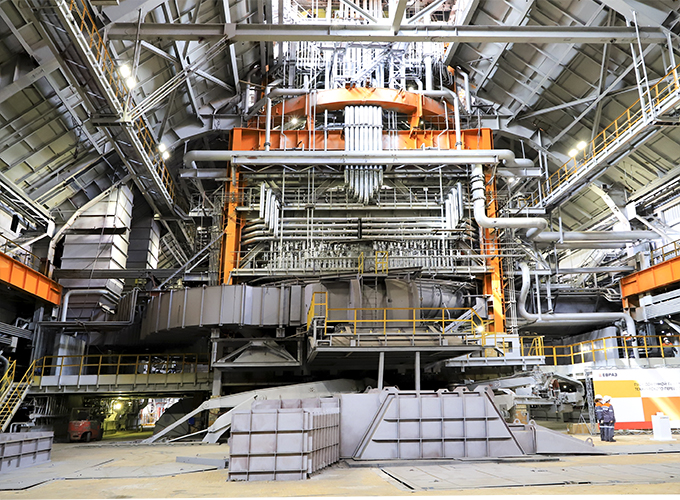

Blast Furnace Ironmaking

Tapping

Stable and reproducible tapping operations are essential for the stable hot metal supply to the steelmaking plant, the hot metal quality as well as for the establishment of a smooth, efficient blast furnace ironmaking process.

Paul Wurth has extensive experience in the design of modern, highly functional casthouses – whether for new furnaces or for modernising existing plants.

Today’s flat casthouse floor layout, runner design and reliable equipment ensure flexible operation, easy maintenance access and best safety conditions. The use of Paul Wurth’s state-of-the-art casthouse dedusting systems and implementing modern filtering technologies makes your blast furnace operation comply with the strictest environmental regulations.

For reliability reasons, Paul Wurth recommends world-class casthouse machinery from TMT – Tapping Measuring Technology, a joint company of Dango & Dienenthal and Paul Wurth. TMT’s full range of proprietary casthouse equipment includes fully hydraulic taphole openers, clay guns and runner cover manipulators as well as tilting runner drives, sampling and measuring devices and auxiliary equipment.

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking