- Home

- About

- Technology

- Blast Furnace Ironmaking

Solutions / Competences

- Direct Reduction

- Cokemaking

Solutions / Competences- Residue treatment

- Intralogistics

- Services

- Shaping the future

- Supply chain

- Worldwide

- News & Events

-

News

8th April 2022

Copper staves replaced using innovative technique at Tata Steel Jamshedpur

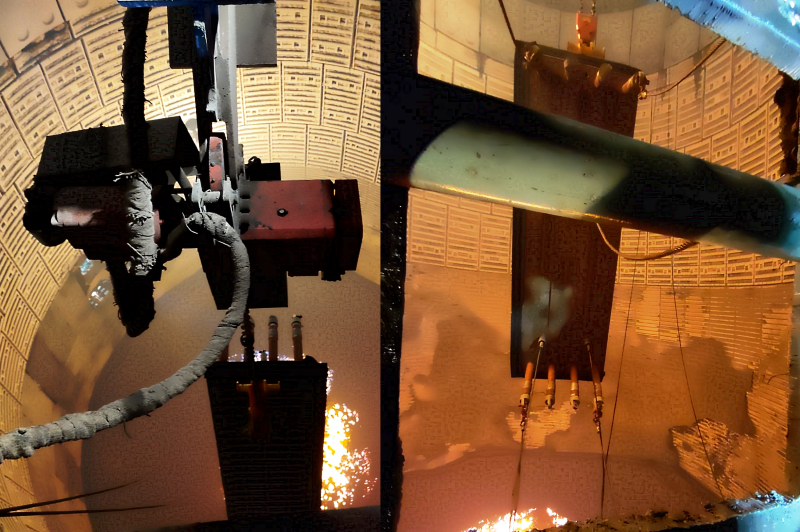

In September 2021, Paul Wurth performed the substitution of five copper staves of Blast Furnace ‘G’ at the Jamshedpur steelworks using an innovative technique specially developed by Paul Wurth.

By making use of a special pneumatic hoist system to be connected to Paul Wurth’s bell less top gear box, the old copper staves can be hooked and removed from their position. The replacements are then sited in front of the installation area, ready to be pulled and affixed to the shell.

This technique does not require entering the furnace and emptying it in order to remove the old copper staves and place new ones. This is a significant safety advantage since it limits the exposure of the operators to potentially noxious gases

An additional advantage is that the total time the blast furnace is shut down is shortened compared to standard technologies: In this case it was limited to just six days.

Paul Wurth provided the erection engineering, supplied of main components, manufactured special tools and tackles and made supervision and labour manpower available on a 24-hour basis.

The project – executed in very close cooperation by the customer was such a success and Tata praised out team’s efforts to enhance safety standards without any delays, despite various unforeseen hurdles, as well as the high quality of the job performed.

This innovative technique enlarges Paul Wurth blast furnace-related servicing portfolio, allowing Paul Wurth to be even more competitive compared to the pure staves suppliers – once again demonstrating our role as Leading Partner in the World of Metals.

32, rue d'Alsace

L-1122 Luxembourg

LUXEMBOURGP.O. Box 2233

L-1022 Luxembourg

LUXEMBOURGTel.: (+352) 4970-1

Fax.: (+352) 4970-2209

Links & Downloads

2024 © Paul Wurth - All rights reserved - Disclaimer - Contact

- Blast Furnace Ironmaking